The Ultimate Sofa Buyer's Guide: Longevity, Quality, and Smart Design Choices

The selection and placement of a sofa set is an investment decision that merits the same rigor as buying a high-end appliance or an heirloom rug. The focus must shift from surface aesthetics to the Total Cost of Ownership (TCO), driven by structural integrity and material resilience. This report is your deep dive into the engineering, design psychology, and advanced maintenance protocols necessary to acquire a sofa that functions as a legacy piece.

Section 1: The Engineering Deep Dive: Evaluating Quality Beyond Upholstery

The expected lifespan of a sofa—whether 5 years or 25 years—is entirely determined by its hidden structural architecture. A high-end sofa is an engineered piece of furniture, not merely a cushioned box.

1.1 The Frame and Joinery: The Rigidity Protocol

The frame is the true skeleton, constantly fighting against gravity, friction, and the sheer inertia of people collapsing onto it.

Kiln-Dried Hardwood: The Science of Stability

The gold standard remains kiln-dried hardwood (oak, maple, beech, or birch). The kiln-drying process is a scientific necessity, reducing moisture content to below 7-8%. This pre-treatment stabilizes the wood, neutralizing its natural tendency to shrink, swell, bow, or warp in response to interior temperature and humidity fluctuations. A frame made from air-dried or non-dried wood will inevitably degrade prematurely, leading to a creaking, unstable frame within a few years.

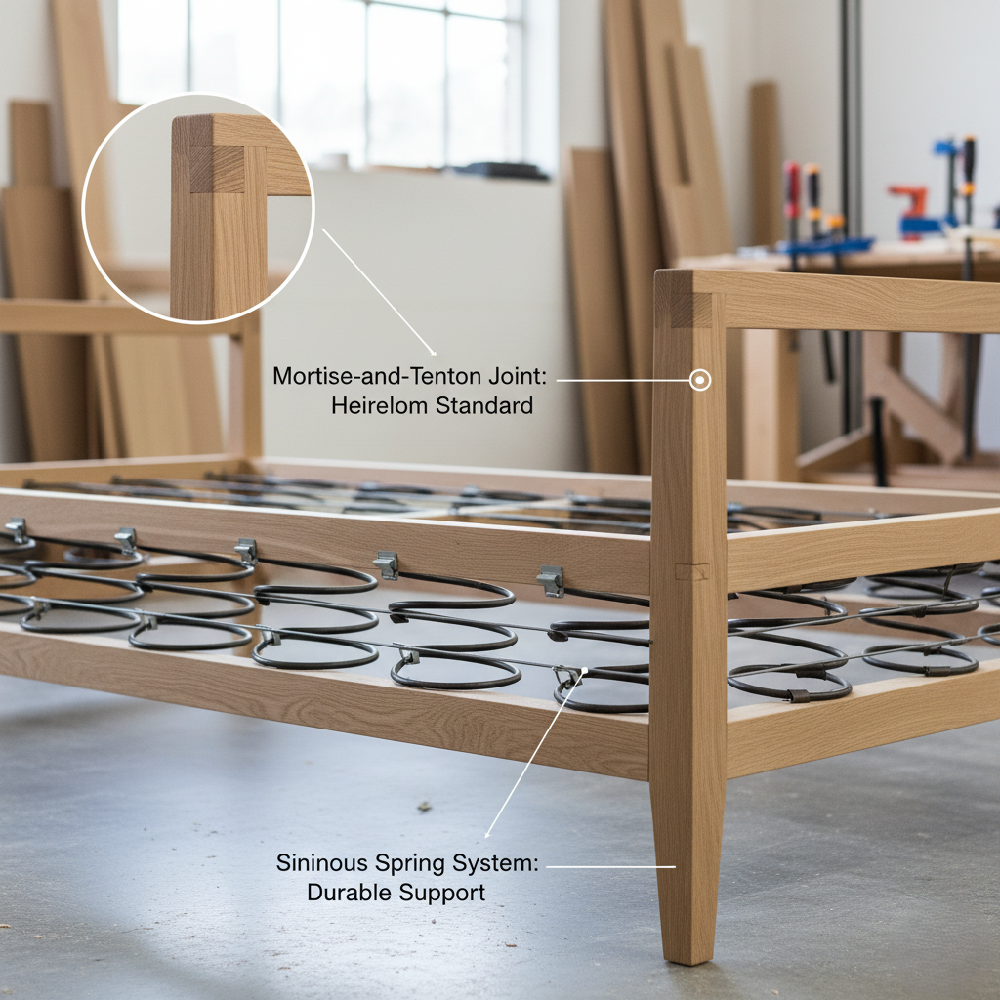

The Joinery Hierarchy

Frame longevity is ultimately guaranteed by the joinery—the connection points. We assess quality by the reliance on carpentry over adhesives:

| Joinery Technique | Quality Level | Rigidity/Longevity Benchmark |

| Mortise-and-Tenon | Heirloom Standard | Highest rigidity. The interlocked wood fibers are self-supporting, requiring minimal glue reinforcement. |

| Double Dowel | Investment Grade | Sturdy, precise connection using multiple pegs. Common in high-volume, quality manufacturing. |

| Corner Block | Mandatory Reinforcement | Solid wood or engineered wood triangles glued and screwed into inner corners. Essential for preventing rack and wobble. |

| Glue and Staples Only | Temporary/Budget | Joints rely solely on adhesive and friction. Prone to immediate failure under lateral stress. Strictly Avoid. |

The Creak Test: A well-built frame should exhibit no twist or audible creaking when lifted slightly from a corner—a telltale sign of weak joinery or insufficient corner blocking.

Revamp your living room! Discover the perfect carpet colors to pair with your brown leather sofa in our new styling guide.

1.2 Suspension Systems: The Backbone of Comfort Retention

The suspension system provides the crucial mechanical support, preventing cushions from sagging directly onto the frame.

-

8-Way Hand-Tied (8-WHT) Springs: This system uses individual coil springs, meticulously tied by hand in eight directions (front-to-back, side-to-side, and diagonally). This web-like structure ensures that the pressure on any single spring is evenly distributed across the entire system. While costly and labor-intensive, it offers individualized, superior support that can be repaired and tuned up, contributing to generational longevity.

-

Sinuous (No-Sag) Springs: For mid-to-high-range pieces, the sinuous spring system is the practical choice. It uses heavy-gauge (8-gauge is ideal) steel S-shaped coils attached to the frame. The essential quality indicator is the presence of at least two horizontal silent-tie wires clipped to each spring. These wires link the springs together, preventing individual springs from moving independently and reducing the potential for squeaking and metal fatigue.

Our new guide reveals 3 easy methods to make any couch taller, even those without legs! Say goodbye to low-rider seating.

1.3 Cushion Fill: Density, Resilience, and the Luxury Wrap

Cushion lifespan is measured not just by comfort but by its ability to rebound and resist permanent compression (sagging).

-

Foam Density: Density is the weight of the foam per cubic foot (a common measure is $1.8 \text{ to } 2.5 \text{ lbs./cu. ft.}$). High-density foam (over $2.0 \text{ lbs./cu. ft.}$) provides firmer support and resists compression for 10+ years. High-Resiliency (HR) foam is the best, offering the highest level of rebound and shape retention.

-

Layering for Luxury: The most durable and comfortable cushions employ a multi-layer system: a resilient high-density foam core for support, wrapped in a layer of synthetic batting (Dacron) for softness, and often finished with a jacket of down and feathers (a $90 \text{ percent}$ feather / $10 \text{ percent}$ down blend) for a plush "crown." This hybrid approach balances the structure of foam with the luxurious feel of natural fill.

Section 2: Upholstery: A Risk-Management Decision

The selection of upholstery is a calculus of aesthetic aspiration versus lifestyle risk.

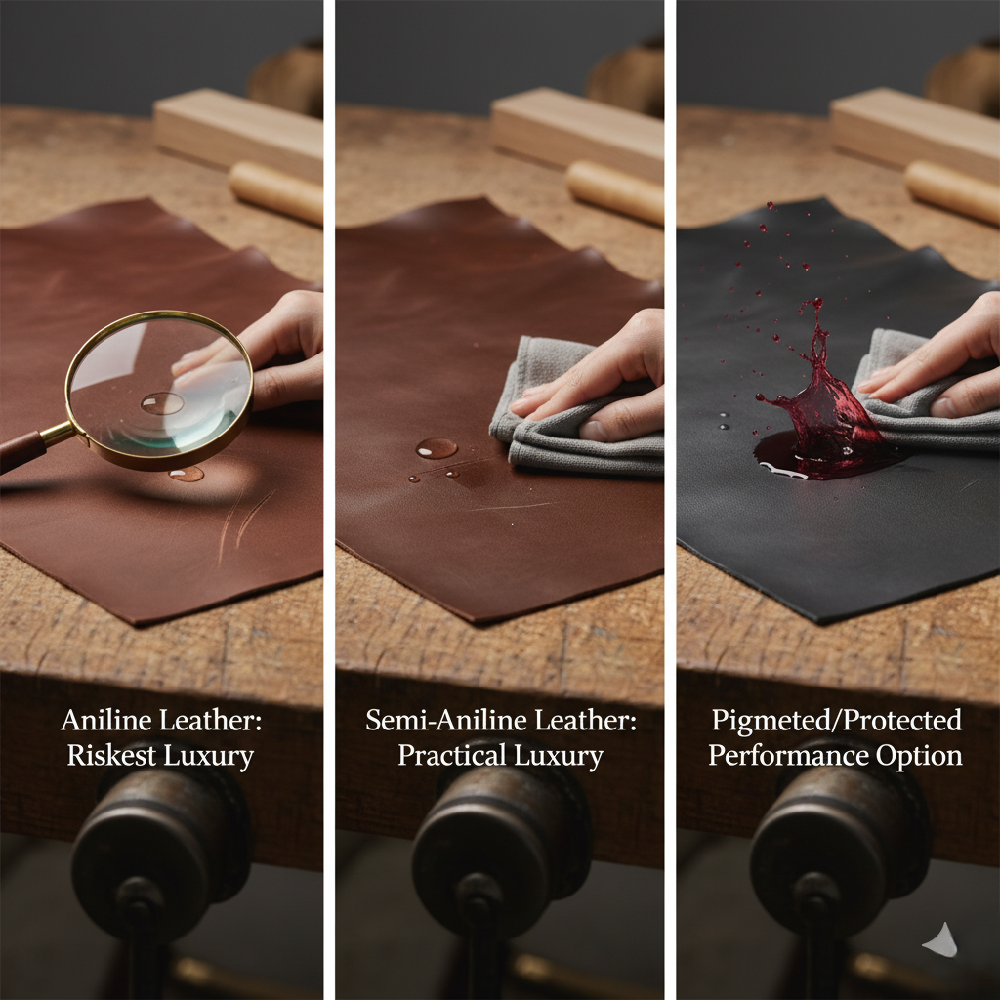

2.1 The Investment Case for Leather

Leather's TCO is superior because it ages rather than deteriorates. A high-quality, full-grain leather piece will develop a rich patina—a soft sheen that develops from age, use, and light.

-

Aniline: The riskiest luxury. It is dyed with no protective coating, showcasing the hide's natural markings. It is extremely vulnerable to UV damage (fading), liquid absorption (staining), and scratching. Recommended only for formal, low-light spaces with minimal human or pet traffic.

-

Semi-Aniline: The practical luxury. It has a light, pigmented coating that offers moderate resistance to spills and sunlight while retaining much of the natural softness and breathability. This is the optimal choice for an investment-grade sofa in a moderate-traffic family environment.

-

Pigmented/Protected: The performance option. The heavy, uniform protective polymer coating sacrifices natural feel for maximum resistance to stains, fading, and heavy wear. Ideal for homes with young children, pets, or commercial use.

2.2 Advanced Fabric Performance

For households preferring fabric, focus on technical specifications beyond simple material type.

-

Double Rub Count: This is the industry standard for durability, measured by a machine repeatedly rubbing an abrasive cotton duck cloth against the fabric until the first thread breaks. A high-traffic residential sofa should have a minimum of $15,000 \text{ to } 20,000 \text{ double rubs}$. Commercial-grade fabrics can exceed $50,000$.

-

Microfiber and Synthetic Velvets: Modern microfiber and synthetic velvets (polyester or rayon) offer superb resistance to snags and spills. Unlike traditional leather, they are less prone to showing permanent, highly visible scratch marks from pet claws, making them a superior choice for pet owners who value low maintenance.

HOW TO CLEAN LEATHER COUCH. Get the expert guide to deep cleaning, conditioning, and 100% odor removal. Your sofa deserves it!

Section 3: Strategic Placement: Zoning and Flow Psychology

A poorly placed sofa can ruin the function of an impeccably designed room. Strategic placement adheres to principles of flow, conversation, and visual scale.

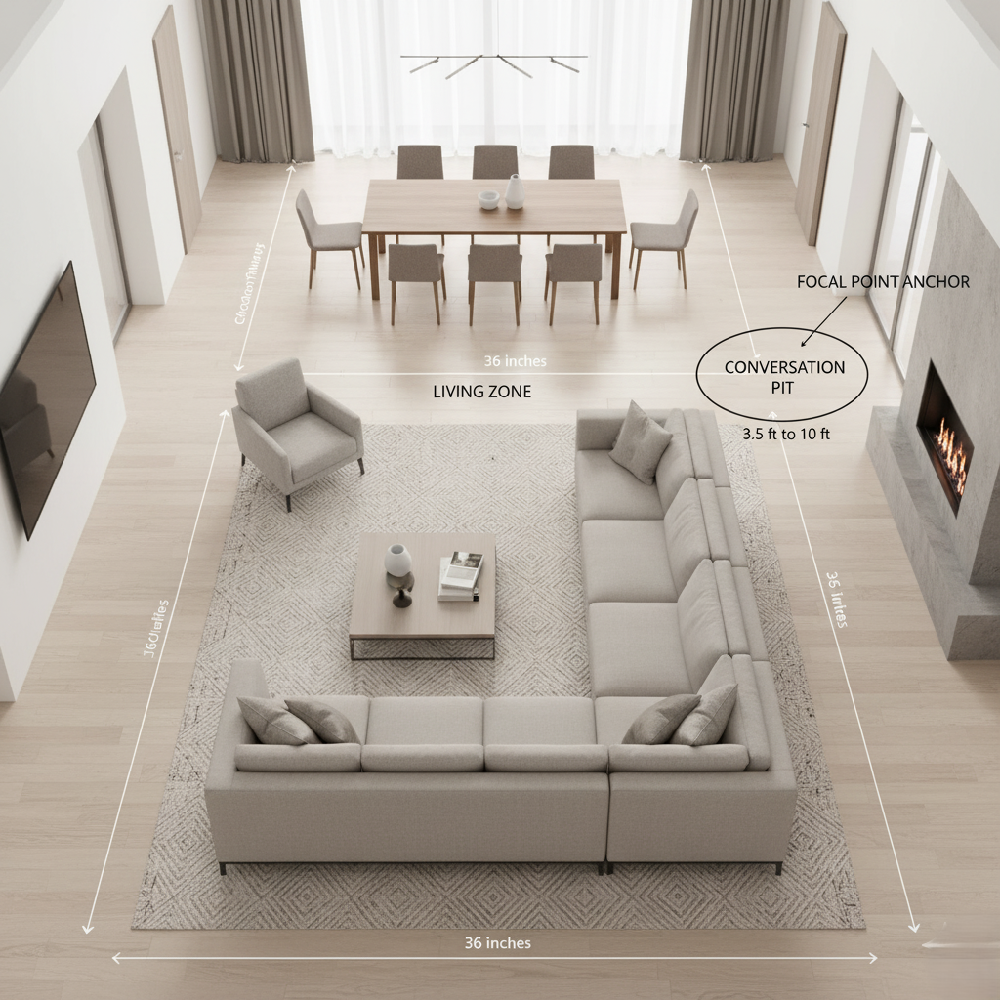

3.1 The Psychology of Conversation and Flow

-

The Conversation Pit Rule: Seating must facilitate easy, natural dialogue. The ideal distance between primary seating pieces (sofa to opposing armchair or sofa) is $3.5 \text{ to } 10 \text{ feet}$. Beyond 10 feet, occupants must raise their voices, breaking the intimacy of the space.

-

Circulation Pathways: The main pathways around furniture groupings must maintain $30 \text{ to } 36 \text{ inches}$ of clearance. Tighter routes (between a sofa and a side table) can be $18 \text{ to } 24 \text{ inches}$. Never block the main entry point to the seating area.

-

The Focal Point Anchor: Every layout must revolve around a focal point (fireplace, window view, or television). The primary sofa should be positioned to face and anchor this focal point, giving the room a natural orientation.

3.2 Mastering L-Shape and Sectional Zoning

Sectionals are potent tools for dividing space in open-concept living/dining/kitchen areas.

-

The Room Divider Technique: Place the sectional so that the back of its longest piece is floating away from the wall and is perpendicular to a main architectural line (like the kitchen island or dining table). The back of the sofa thus acts as a low, subtle wall, defining the "living zone" without sacrificing the open feel.

-

Grounding with the Rug: The area rug is the single most important tool for anchoring a floating sectional. The rug must be large enough to sit under all front legs of every major piece (all sectional segments and the coffee table). A rug that is too small makes the entire seating arrangement look like it is floating aimlessly in the room.

Section 4: Longevity and Restoration Protocols

The final stage of investment protection is implementing a proactive maintenance plan that includes deep cleaning and, eventually, restoration.

4.1 Advanced Leather Conditioning and Restoration

Leather longevity is entirely dependent on retaining natural oils.

-

The Conditioning Cycle: Apply a high-quality, lanolin-based or oil-based leather conditioner every three to six months. This prevents the fibers from drying out, cracking, and becoming brittle—the number one cause of leather failure. Avoid silicone or wax-based products, which can clog the pores of the leather and cause premature deterioration.

-

Grease Spot Management: On high-quality aniline or semi-aniline leather, greasy stains (like those from hands or hair) are often best left alone after blotting the excess. The natural oils in the leather will eventually absorb and disperse the grease, contributing to the desirable patina. For stubborn, fresh grease, applying a light dusting of cornstarch or baking soda to absorb the oil overnight can be effective.

4.2 Specialized Fabric Care and UV Damage Mitigation

-

Velvet Rejuvenation: When velvet’s pile becomes crushed or shiny, it can be restored with a steam treatment. Use a handheld steamer or an iron on its lowest steam setting, holding it $1 \text{ to } 2 \text{ inches}$ above the fabric. Brush the steamed area against the direction of the pile to lift the fibers and restore volume.

-

The UV Protocol: Prolonged exposure to direct sunlight causes photodegradation in fabric and accelerates the drying and fading of leather. Position the sofa strategically, or, for high-value pieces, apply UV-filtering window film or use heavy, lined drapery during peak sunlight hours. This is crucial for maintaining the color integrity of Aniline leathers and bold-colored fabrics.

A high-quality sofa is a promise—a commitment from the manufacturer to deliver decades of structural integrity and comfort. By demanding transparency on kiln-drying, joint construction, and suspension gauge, and by implementing a rigorous maintenance and placement strategy, the purchaser ensures the investment delivers a return that lasts for a generation.

From thrones of power to your cozy living room: Dive into the fascinating evolution of the sofa! 🛋️Discover the hidden history of your favorite couch in our latest blog post!